No More Mistakes with Flour Mill Machine Manufacturer

Mar 11 2023

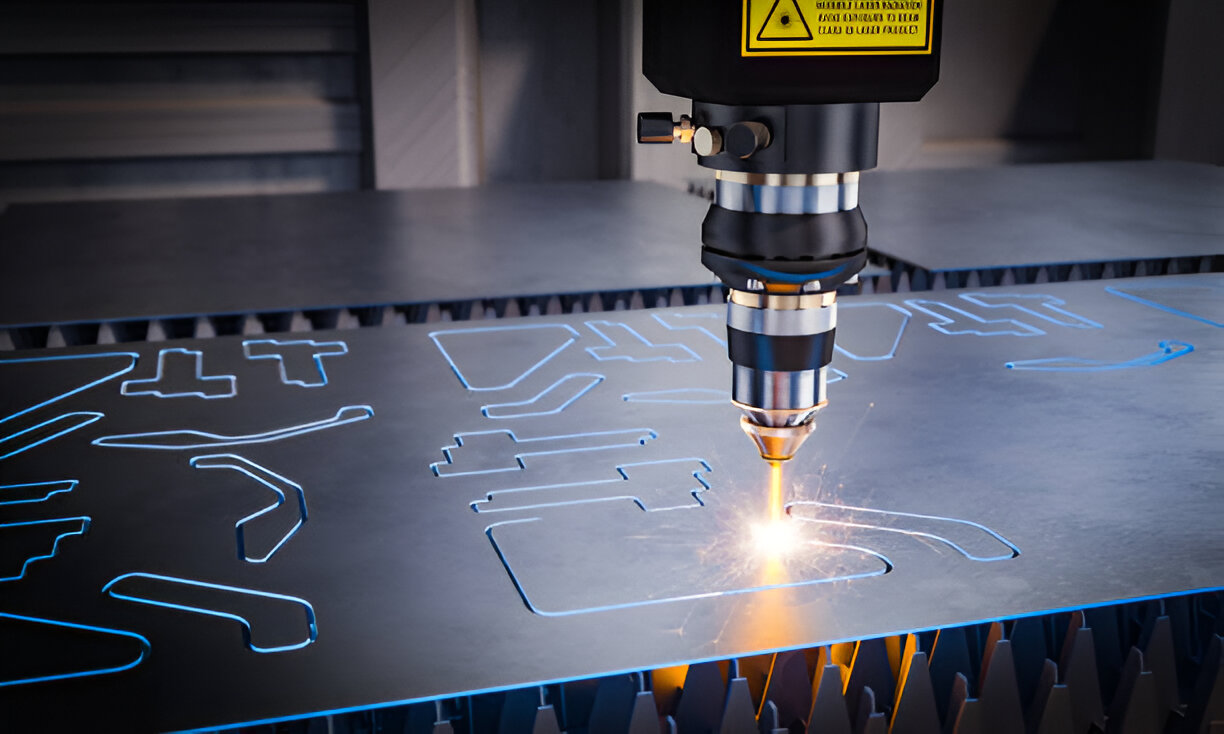

In the modern world of manufacturing and customization, precision is key. Whether you're a small business owner or part of a large manufacturing operation, investing in a laser engraving machine can significantly improve the quality of your products, enhance operational efficiency, and drive profitability. With the versatility, speed, and precision offered by advanced laser engraving machines, they’ve become an essential tool across industries such as automotive, electronics, jewelry, and personalized goods. If you’re considering elevating your business, here's why a laser engraving machine should be your next investment.

Laser engraving technology has revolutionized the way businesses approach product customization, branding, and production. Here are a few key reasons why investing in a laser engraving machine makes sense for your business:

Laser engraving machines deliver exceptional precision, ensuring that even the most intricate designs, logos, and patterns are accurately reproduced. With their ability to engrave at extremely fine resolutions, these machines can etch detailed artwork or text onto various materials like metal, wood, plastic, glass, and more. This level of precision is vital for industries that demand high-quality engraving for branding, identification, or decorative purposes, such as luxury goods, jewelry, and medical devices.

One of the biggest advantages of laser engraving machines is their speed. These machines can complete engraving tasks much faster compared to traditional methods, allowing you to process high volumes of items quickly and efficiently. Whether you need to mark serial numbers on products, create personalized gifts, or engrave large quantities of items for an event, laser engraving machines can handle the task with minimal downtime, ensuring quicker turnaround times and greater production output.

Laser engraving machines are incredibly versatile and can be used on a wide range of materials. This makes them ideal for businesses involved in different sectors. For example:

Metal engraving – Create durable engravings on various metals like aluminum, stainless steel, and brass.

Wood engraving – Create intricate designs, logos, and patterns on wood for signage, awards, or custom products.

Glass engraving – Perfect for personalizing glassware, trophies, and awards.

Plastic engraving – Ideal for creating custom engravings on plastic items, labels, and packaging.

With a laser engraving machine, you’ll be able to cater to a diverse set of customer needs, giving you a competitive edge in the market.

Compared to traditional engraving methods, laser engraving machines have lower maintenance requirements and operating costs. There are no consumables like ink or chemicals to purchase, and the maintenance costs are typically minimal. This makes the machines more cost-effective in the long term, as you won’t need to spend on additional materials or frequent repairs. Additionally, the durability of laser engravers ensures they last for years, offering a high return on investment.

Laser engraving is an environmentally friendly process. Since it requires no ink, chemicals, or solvents, it significantly reduces waste and harmful emissions compared to traditional engraving methods. Furthermore, the non-contact nature of laser engraving means there’s no risk of damaging the material being engraved, providing a safer, cleaner, and more efficient solution.

Laser engraving machines are widely used across various industries for a wide range of applications:

Personalization – Engraving names, logos, and designs on gifts, jewelry, and promotional products.

Industrial Manufacturing – Marking serial numbers, barcodes, and part identification numbers on machine components and tools.

Automotive – Engraving logos and identification marks on engine parts, dashboards, and accessories.

Electronics – Engraving labels, serial numbers, and designs on circuit boards, phone cases, and other electronic devices.

Medical Devices – Creating precise, permanent engravings on surgical instruments, medical devices, and implants.

The flexibility of laser engraving machines means you can easily cater to the needs of various industries and provide customized solutions for your customers.

Investing in a laser engraving machine is a strategic decision for your business. To maximize your return on investment, consider the following:

Select the Right Machine – Ensure the laser engraver you choose is suitable for your material types, production volume, and required engraving precision.

Train Your Team – Proper training ensures that you get the most out of your engraving machine, improving productivity and minimizing errors.

Offer Customization Services – Leverage the versatility of the laser engraver to offer personalized products, opening up new revenue streams.

Invest in Marketing – Promote your engraving capabilities and highlight the unique products you can offer, such as customized gifts or branded corporate items.

By making these smart moves, you’ll ensure that your laser engraving machine becomes an asset that helps grow your business and increase profits.

A laser engraving machine is a game-changing investment for any business looking to enhance production efficiency, offer high-quality customization, and stay ahead in a competitive market. From small startups to large-scale enterprises, the precision, speed, and versatility of these machines provide a significant competitive advantage. Whether you’re engraving on wood, metal, or plastic, you’ll achieve consistent, high-quality results every time.

Social Media Marketing Strategies for Beginners

Mar 14 2023

(0) Comments