No More Mistakes with Flour Mill Machine Manufacturer

Mar 11 2023

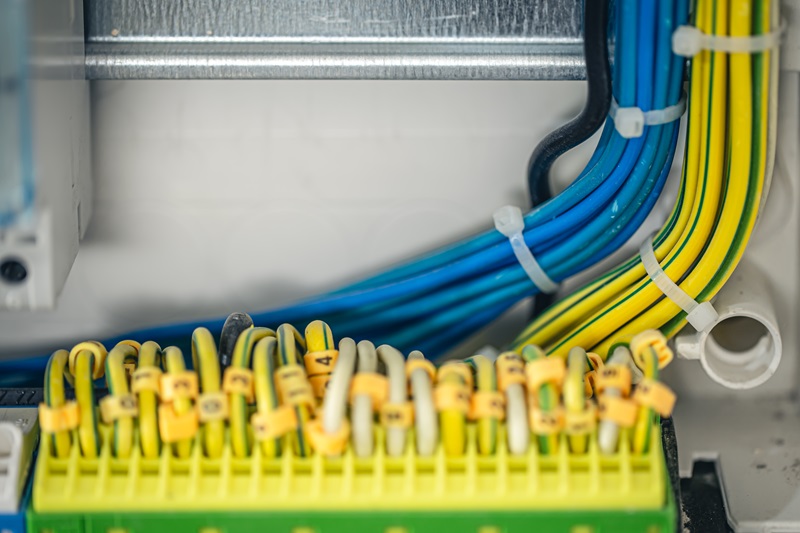

Have you ever looked under the bonnet of your car and wondered how all those wires stay organized? Or peeked behind a wall panel in your home, only to see a tidy nest of cables secured in place? These neat arrangements are often made possible by one of the most underrated inventions in the world of wiring: cable tie mounts. When you think about day-to-day tasks in electrical and automotive work, a big part of the job involves keeping cables tidy, protected, and easy to access.

In this blog post, we’ll explore exactly why cable tie mounts are such a game-changer for anyone working with wiring—whether in a sleek automotive workshop or a busy electrician’s van. Along the way, we’ll also examine how simple zip ties (often called cable ties) function, the key differences between terms like “zip tie vs cable tie,” and what makes certain ties stronger and more durable than others. By the end, you’ll know how to choose the right cable tie mount for every project and understand how these tiny components can make a surprising difference in your wiring tasks.

Cable tie mounts might sound small and ordinary, but they have a critical role in holding complex systems together. Picture this: you’re working on your home entertainment center or an automotive repair project in Australia, and the area is swarmed with power cables, data cables, and various types of hoses. Without a proper way to secure things, those cables can get tangled or damaged. That’s where cable tie mounts step in. They act as a firm anchor for your cable ties, allowing you to clamp down wires and keep them stable in any environment.

In electrical setups, tangled cables can lead to short circuits or even fire hazards. Meanwhile, in automotive applications, any rattling wire could lead to a loss of function or a safety problem on the road. By using cable tie mounts, you’re not only tidying up but also making sure everything stays locked in place over time. This minimizes the risk of damage caused by vibrations, friction, or accidental tugs. As a bonus, such organization pays off when you need to modify or troubleshoot wiring later. Instead of fishing through a messy jumble of cords, you can instantly spot and fix the specific wire. That’s a huge timesaver, especially when you’re under pressure in a workshop or out on the freeway.

Now that we’ve highlighted how cable ties themselves function, let’s turn our attention to the mounts that hold these ties in place. Using cable ties without a mount can sometimes be enough, but adding a mount offers a permanent, more organized approach. It’s like upgrading from simply stacking items in a corner to placing them on labelled shelves. With a cable tie mount, each tie has a designated anchor point, which keeps everything locked and lined up.

One of the biggest advantages of mounting cable ties is securing wires so they have minimal movement. Imagine you’re dealing with the wiring harness for an automotive engine. If it’s left loosely hanging, vibrations and friction could cause insulation to wear down over time. Cable tie mounts attach to the vehicle’s chassis or another stable surface, giving each wire or hose a dedicated route. This approach minimizes overlap, reduces pinch points, and keeps the entire system more orderly.

In an electrical context, stray cables are a recipe for trouble. They can become tripping hazards, get pinched in cabinet doors, or short out if insulation rubs off. By mounting your cable ties, you ensure the cables run safely along a designated path. In an automotive scenario, a loose wire that touches the engine block may be subjected to heat and friction, causing caked or melted insulation. Cable tie mounts reduce these risks by offering a consistent, secure route away from extreme heat or moving parts.

Whether you’re fitting new lighting in your garage or upgrading the entertainment system in your use, cable tie mounts act as a stable foundation. They deliver benefits like improved airflow around wires (reducing the risk of overheating), easier cleaning or maintenance, and a more professional look. Plus, for anyone who frequently modifies their electrical or automotive setups, having a systematic route for cables means changes are simpler. You avoid rummaging through messy tangles and instead unclip only the ties that need adjustments.

It’s one thing to pick a heavy-duty cable tie, but without the right mount, your cables might not stay secure over time. Cable tie mounts come in multiple materials, shapes, and mounting options, making it essential to consider a few key factors before you buy. After all, the mount is the anchor that keeps the entire assembly in place.

Most cable tie mounts are made from nylon or a similar plastic because they’re strong, lightweight, and cost-effective. However, if your project is exposed to harsh chemicals, extreme heat, or high moisture levels, you may need mounts made of specialized plastics or even metal. For example, in a marine environment, a stainless steel mount wouldn’t corrode easily. In an industrial setting with high chemical exposure, you’d want a mount built to resist etching or weakening. Matching the material to the environment is critical for long-lasting performance.

Mount sizes vary. Some are discreet for small wires behind your home TV stand, while others can hold heavier wiring harnesses in engine compartments. Always check the recommended weight capacity, which should be listed by the manufacturer. Remember, it’s not just about the weight of the cable bundle but also the stress caused by vibrations or movement. Aim for a mount that slightly exceeds your estimated load, ensuring a reliable hold even under dynamic conditions like driving on rough roads.

One common error is attaching a mount with the wrong adhesive or hardware. If you’re sticking a mount to a painted surface that isn’t fully cleaned or prepped, it might peel off when you least expect it. Another oversight is failing to consider the temperature range, which could cause the mount to crack or lose grip in extreme Australian summers. Lastly, some folks mix and match ties and mounts from different materials without checking compatibility. Always confirm that your mount and your chosen cable ties work well together.

Securing electrical and automotive wiring is critical if you want to keep your systems safe, organized, and long-running. Cable tie mounts serve as the backbone for this task, providing a stable place to attach cable ties so they stay locked in place. By pairing the right type of mount with the correct cable tie—whether heavy-duty nylon or stainless steel—you can protect your wiring, avoid hazards, and streamline any maintenance tasks that come up later.

Throughout this post, we’ve explored the ins and outs of cable tie mounts, including the best practices for use in both electrical and automotive settings. From preventing pinched insulation to keeping wires neat and tidy, these mounts work hand in hand with cable ties to deliver the reliability and peace of mind every DIY-er and professional seeks. Plus, we covered some of the most common questions about the strongest zip ties and the differences between “zip tie vs cable tie” terms.

Social Media Marketing Strategies for Beginners

Mar 14 2023

(0) Comments