No More Mistakes with Flour Mill Machine Manufacturer

Mar 11 2023

Prepreg composites are playing an enormous role in the current high-tech world of engineering and production. What are they though, and why are they found to be so crucial in things such as an aerospace industry, automotive, and sports equipment?

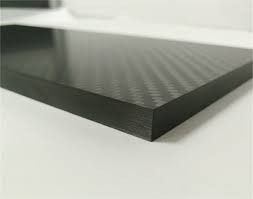

Prepreg is short for pre-impregnated fibers of composite. This implies that the reinforcing fibers (in most cases, carbon, glass, and also aramid) are already compounded with a resin system, in most cases an epoxy, by the time they are utilized in a final product. This blend is well done under rigid conditions with flawless dispersion of resin in the fibers.

So, prepreg composites are very lightweight with good strength properties, durability, precision. There is no guessing when it comes to the production since the resin is pre-applied. The result is a greater degree of consistency, a reduction in errors and improved performance all-round. They are the adoration of engineers and designers who are capable of designing parts that are extremely powerful but are much lighter in weight than metal alternatives.

Just imagine a race car, a plane wing or yet an excellent bike. All these must be as lightweight as you can make it and be in a position to withstand intense stress. Prepreg composites are where all that comes in. They are able to take harsh conditions, absorb shocks and retain their shape even after so many years.

The other major benefit is that they are clean and efficient to work with. The pre-measuring and preparing allows the manufacturers to trim losses and better turnaround times because everything is there. Furthermore, prepregs are commonly kept at a cold temperature to prolong the shelf life and later in an autoclave or oven at high temperature and pressure to form the final, solid-to-solid structure.

Even in the industries where precision, performance, safety is of the first importance, prepreg composites have found their way into the go-box.

To sum it up: Prepreg composites are helping push technology forward by providing lightweight, high-strength materials that meet the demands of today’s most advanced applications. Whether it's flying in the sky, racing on a track, or cruising across the ocean, these materials are quietly powering the future.

Social Media Marketing Strategies for Beginners

Mar 14 2023

(0) Comments