No More Mistakes with Flour Mill Machine Manufacturer

Mar 11 2023

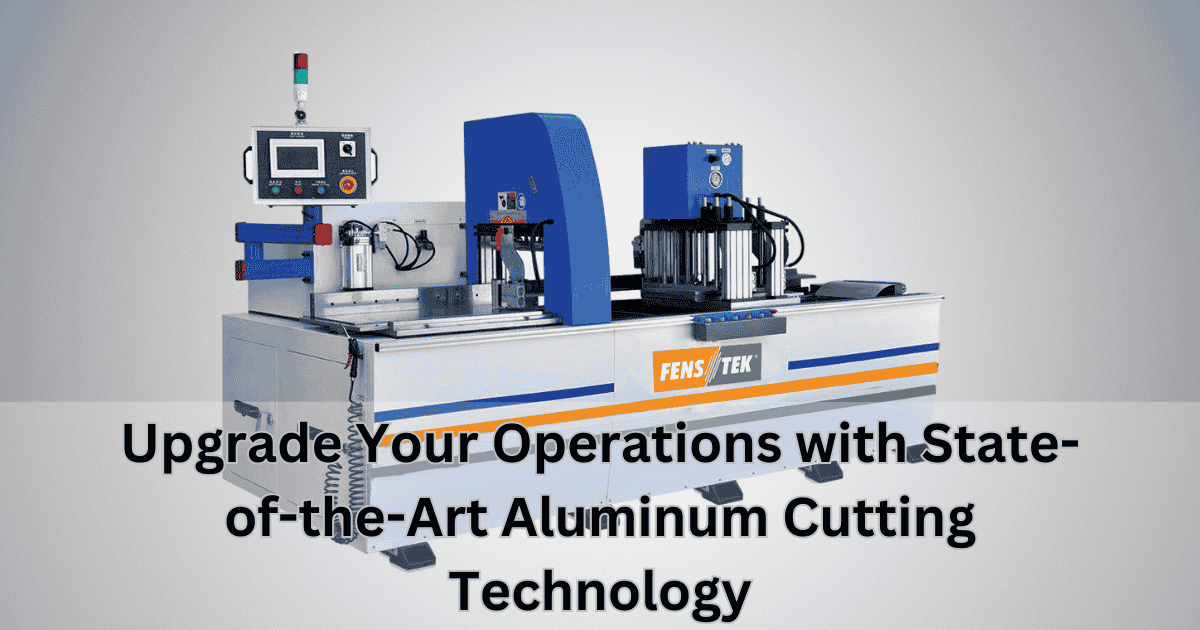

In today's fast-paced industrial landscape, staying ahead of the competition requires more than dedication and hard work—it demands innovation and adopting cutting-edge technologies. Investing in state-of-the-art aluminum cutting technology is no longer a luxury but a necessity for aluminum fabrication and manufacturing businesses. Upgrading your operations with advanced aluminum cutting machines can significantly enhance efficiency, precision, and overall productivity, propelling your business to new heights.

Aluminum, known for its lightweight and high-strength properties, is fundamental in various industries, including aerospace, automotive, construction, and electronics. The demand for aluminum products is escalating, and so is the need for precision and efficiency in cutting and shaping this versatile metal. Traditional cutting methods often fail to meet the high standards required in modern manufacturing processes.

These challenges underscore the importance of upgrading to advanced aluminum cutting technology.

Investing in modern aluminum cutting machines offers many benefits that can transform your operations.

State-of-the-art cutting machines utilize advanced technologies such as CNC (Computer Numerical Control), laser, and plasma cutting systems. These technologies allow for exact cuts with minimal tolerances, resulting in a higher-quality end product that meets exact specifications and reduces the need for secondary processing and rework.

Modern machines are designed for speed without compromising accuracy. High cutting speeds and automation features enable faster task completion, significantly boosting production rates. Automated material handling and nesting capabilities optimize the use of materials, reducing waste and lowering costs.

Advanced cutting technology supports a wide range of cutting methods and materials. Modern machines can easily handle diverse projects, Whether straight cuts, intricate patterns, or complex shapes. This versatility allows your business to expand its service offerings and cater to a broader market.

While the initial investment may seem substantial, the long-term cost savings are considerable. Reduced material waste, lower energy consumption, decreased labor costs due to automation, and minimal maintenance downtime all contribute to a significant return on investment (ROI).

Safety is paramount in any industrial setting. Modern aluminum cutting machines have safety features like enclosed cutting areas, automatic shut-offs, and advanced sensors. These features protect operators from hazards and ensure a safer working environment.

The latest cutting machines are designed to integrate seamlessly with Industry 4.0 practices. Internet of Things (IoT) connectivity, real-time data analytics, and remote monitoring enable you to make informed decisions, predict maintenance needs, and optimize operations.

Consider a mid-sized fabrication company that upgraded its operations by investing in a CNC aluminum cutting machine. Before the upgrade, the company faced challenges meeting tight tolerances and experienced frequent delays due to machine malfunctions.

Post-upgrade results included:

This transformation showcases the tangible benefits state-of-the-art aluminum cutting technology can bring your business.

Selecting the right equipment tailored to your specific needs is essential when considering an upgrade.

Factors to Consider:

Collaborating with a reputable aluminum cutting machine manufacturer is crucial. They can provide expert guidance, customized solutions, and ongoing support to ensure you maximize your investment.

Upgrading your operations is a strategic move that positions your business for future growth and competitiveness. The initial investment is justified by the considerable advantages—enhanced quality, increased efficiency, cost savings, and the ability to meet the evolving demands of the market.

Steps to Get Started:

Integration with Industry 4.0

The latest cutting machines are designed to integrate seamlessly with Industry 4.0 practices. Internet of Things (IoT) connectivity, real-time data analytics, and remote monitoring enable you to make informed decisions, predict maintenance needs, and optimize operations.

In the competitive aluminum fabrication and manufacturing landscape, staying stagnant is not an option. Upgrading to state-of-the-art aluminum cutting technology can enhance your operations, deliver superior products, and exceed customer expectations. By embracing innovation and modernization, you're investing not just in machines but in your business's future success.

Take the first step towards modernization by exploring advanced aluminum cutting solutions tailored to your needs. Partner with industry leaders committed to your success and experience firsthand the difference that cutting-edge technology can make.

Social Media Marketing Strategies for Beginners

Mar 14 2023

(0) Comments