No More Mistakes with Flour Mill Machine Manufacturer

Mar 11 2023

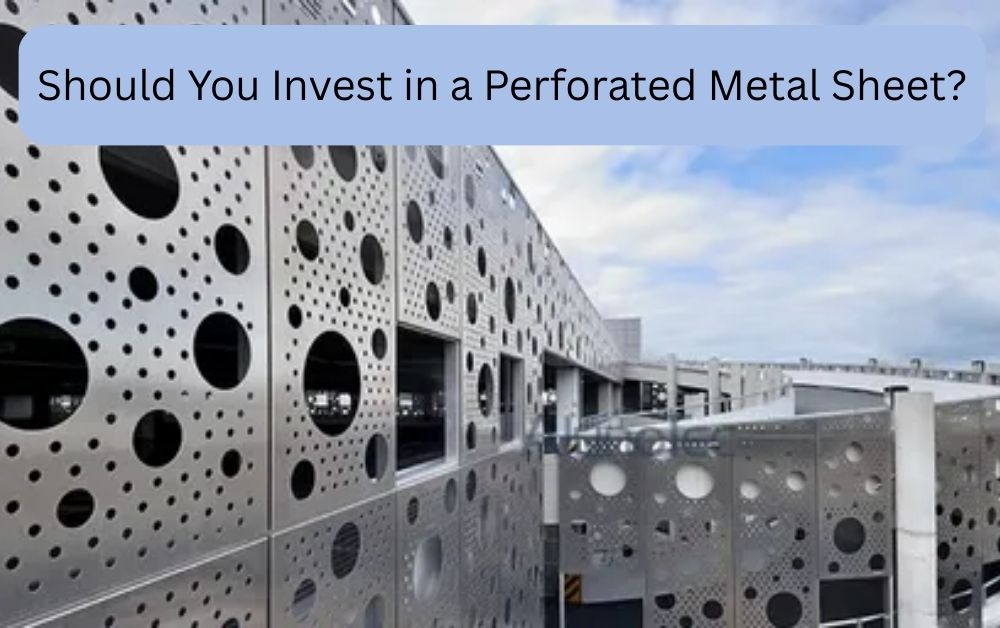

When it comes to versatile and functional building materials, Perforated Metal Sheet stands out as a top choice across numerous industries. Known for its unique combination of strength, aesthetic appeal, and utility, this material is increasingly being incorporated into architectural designs, industrial projects, and even artistic endeavors. If you are wondering whether it is worth investing in a Perforated Metal Sheet, this detailed guide will help you understand its benefits, applications, and critical considerations.

A Perforated Metal Sheet is essentially a thin metal sheet that has been mechanically stamped or punched with a pattern of holes, slots, or decorative shapes. These holes can vary in size, shape, and arrangement depending on the specific application requirements. The primary materials used to create perforated sheets include stainless steel, aluminum, galvanized steel, and copper.

The perforation process not only reduces the weight of the sheet but also enhances its visual appeal, improves airflow, and allows for light filtration, making it highly useful in a variety of settings.

Investing in a Perforated Metal Sheet offers numerous advantages:

Perforated metal brings a modern and stylish look to any space. Whether used for building facades, interior partitions, or decorative panels, the material offers endless design possibilities that enhance the visual value of structures.

The perforations allow air to circulate freely, making these sheets ideal for applications that require ventilation, such as HVAC systems, sunscreens, and industrial filtration units.

Despite the perforations, a Perforated Metal Sheet retains much of its original strength while becoming significantly lighter. This property makes it easier to handle, install, and maintain without compromising on structural integrity.

These sheets are often used in acoustic panels to absorb sound and reduce noise levels in auditoriums, offices, and industrial plants. The design and pattern of perforations can be customized to optimize sound absorption.

In building design, perforated metal can serve as an effective shading device, reducing solar heat gain and thus lowering energy costs for cooling systems.

Most Perforated Metal Sheets are made from recyclable metals, making them an eco-friendly choice for sustainable construction and manufacturing projects.

The versatility of Perforated Metal Sheets allows them to be used in a wide range of applications across multiple sectors.

Perforated metal: It provides both functional benefits like shading and aesthetic qualities that complement modern architectural styles.

In the industrial sector, perforated sheets are used for machinery guards, filtration systems, and ventilation panels. Their strength and resilience make them suitable for harsh operating environments.

In vehicles, Perforated Metal Sheets are used for grilles, vents, and protective screens. Their lightweight nature helps in reducing overall vehicle weight, contributing to better fuel efficiency.

Modern furniture designers incorporate perforated metals into chairs, tables, and shelving units to achieve a sleek, minimalist look while maintaining durability.

In farming and food production, perforated metal is used for seed sorting, drying racks, and ventilation systems due to its hygienic properties and ease of cleaning.

Selecting the right material for your Perforated Metal Sheet depends on the specific needs of your project. Here are the most commonly used materials:

Known for its corrosion resistance and durability, stainless steel perforated sheets are ideal for outdoor and hygienic applications such as hospitals, kitchens, and marine environments.

Aluminum is lightweight and resistant to corrosion, making it perfect for architectural facades, decorative applications, and transportation uses.

This material offers excellent corrosion resistance at a more affordable price compared to stainless steel, making it a popular choice for industrial and agricultural purposes.

For applications that require both aesthetics and antimicrobial properties, copper and brass perforated sheets are often used, especially in decorative and artistic installations.

Before purchasing a Perforated Metal Sheet, several factors must be taken into account to ensure it meets your project requirements.

The size, shape, and arrangement of the perforations directly affect functionality. For instance, smaller holes may be better for filtration, while larger holes are ideal for decorative purposes.

Choosing the correct metal type is crucial based on the environment it will be exposed to. Corrosive environments demand materials like stainless steel or specially coated metals.

Thicker sheets provide greater strength but may be heavier and more challenging to work with. The right balance must be achieved based on the intended application.

Various finishes such as powder coating, anodizing, or painting can enhance the durability, corrosion resistance, and appearance of the sheet.

While Perforated Metal Sheets offer significant value, they can vary widely in price depending on material, perforation complexity, and customization. It is important to balance quality with budgetary constraints.

Considering the numerous benefits and wide-ranging applications, investing in a Perforated Metal Sheet can be a highly profitable decision. Here are some reasons why it stands out:

The durability of perforated metal means fewer replacements and lower maintenance costs over time, providing excellent long-term value.

Manufacturers offer extensive customization options in terms of hole patterns, sizes, shapes, and sheet dimensions, allowing you to tailor the material to your exact specifications.

Using recyclable materials and energy-efficient designs, Perforated Metal Sheets contribute to eco-friendly building certifications like LEED (Leadership in Energy and Environmental Design).

With growing trends toward sustainable construction, modern architecture, and industrial efficiency, the demand for perforated metal continues to rise, making it a future-proof investment.

Despite their popularity, there are several misconceptions surrounding Perforated Metal Sheets:

Myth: They are too weak for structural use.

Reality: Properly selected and designed sheets maintain considerable strength.

Myth: They are only used for decoration.

Reality: They serve critical functions such as filtration, ventilation, and sound absorption.

Myth: They are prohibitively expensive.

Reality: Costs vary and can be managed based on material and complexity of the perforation.

If you are looking for a material that offers strength, versatility, aesthetics, and sustainability, investing in a Perforated Metal Sheet is an excellent choice. Whether your project is architectural, industrial, automotive, or artistic, perforated metal delivers both functional and visual advantages. By understanding the key benefits, applications, and considerations outlined above, you can make an informed investment that will yield significant returns in both performance and longevity.

For more insightful articles related to this topic, feel free to visit: blogsubmissionsite

Social Media Marketing Strategies for Beginners

Mar 14 2023

(0) Comments