No More Mistakes with Flour Mill Machine Manufacturer

Mar 11 2023

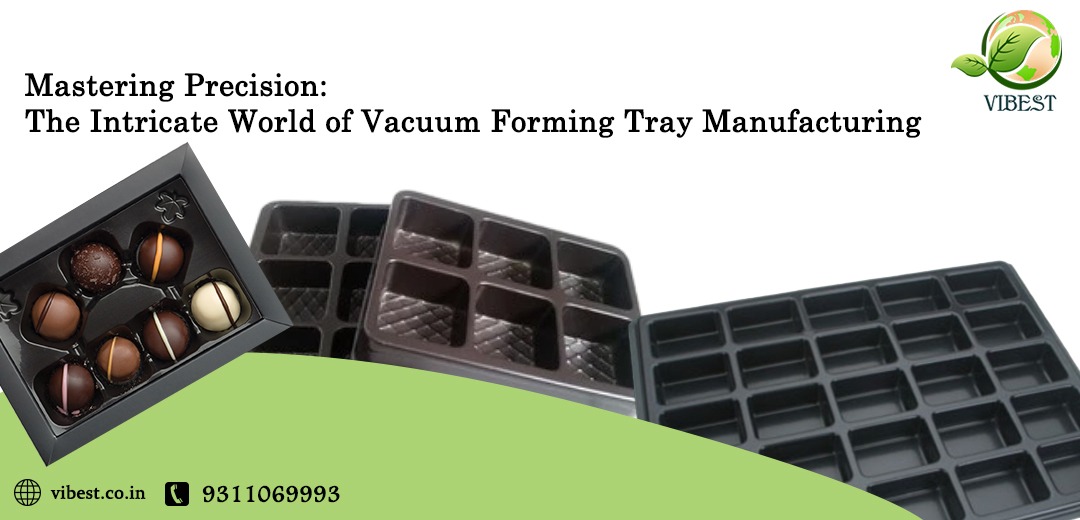

In the realm

of packaging and product protection, vacuum forming trays play a pivotal role

in ensuring the safe transit and display of various goods. At the forefront of

this industry stands a key player - a vacuum forming tray

manufacturer of distinction. This article delves into the world of

vacuum forming tray manufacturing, unraveling the techniques, applications, and

the mastery that goes into producing these precision-engineered solutions.

I. The Essence of Vacuum Forming:

Before

delving into the manufacturing intricacies, it's essential to understand the

fundamentals of vacuum forming. This process involves heating a thermoplastic

sheet until it becomes pliable, draping it over a mold, and using a vacuum to

shape it into the desired form. Vacuum forming trays are crafted using this

technique, providing a cost-effective and versatile solution for packaging

diverse products.

II. Crafting Precision: The

Manufacturing Process:

The heart of

any vacuum forming tray manufacturer's expertise lies in its manufacturing

process. This section explores the step-by-step journey of transforming raw

thermoplastic sheets into intricately designed and functional vacuum forming

trays. From material selection and mold creation to the actual forming process,

readers gain insights into the craftsmanship that defines these trays.

III. Materials Matter: The Role of

Thermoplastics:

The choice

of materials is a critical aspect of vacuum forming tray manufacturing. This

section delves into the various thermoplastics used in the process,

highlighting their unique properties and suitability for different

applications. Whether it's the clarity of PETG, the toughness of ABS, or the

versatility of PVC, the article explores how material selection impacts the

final product's performance and durability.

IV. Applications Across Industries:

Vacuum

forming trays find applications across a multitude of industries, from food

packaging to electronics and healthcare. This section takes a closer look at

the versatility of vacuum forming trays and their adaptability to diverse

product shapes and sizes. Case studies and examples illustrate how these trays

provide tailored solutions to meet the specific needs of different industries.

V. Design Innovation and

Customization:

A key

strength of vacuum

forming tray manufacturer lies in their ability to innovate and

customize designs based on client requirements. This section explores the

design considerations and customization options available, emphasizing how

manufacturers collaborate with clients to create trays that not only protect

but also enhance product presentation and branding.

VI. Sustainability in Vacuum Forming:

As

sustainability becomes a focal point across industries, vacuum

forming tray manufacturers are increasingly adopting eco-friendly

practices. This section explores how the industry is moving towards recyclable

and biodegradable materials, energy-efficient manufacturing processes, and

waste reduction initiatives. The commitment to environmental responsibility is

a crucial aspect of the modern vacuum forming tray manufacturing landscape.

VII. Quality Assurance and

Compliance:

The

reliability of vacuum forming trays is paramount, especially when they are

tasked with safeguarding delicate or valuable products. This section delves

into the quality assurance measures implemented by manufacturers, from rigorous

testing procedures to compliance with industry standards. Certifications and

adherence to regulations ensure that the trays meet the highest quality

benchmarks.

VIII. Technological Advancements and

Automation:

In the

fast-paced world of manufacturing, embracing technology is essential for

efficiency and precision. This section explores how vacuum forming tray

manufacturers leverage technological advancements and automation in their

processes. From computer-aided design (CAD) to automated forming equipment,

readers gain insights into the cutting-edge tools shaping the industry.

As a master

of precision in the manufacturing world, a vacuum forming tray

manufacturer plays a crucial role in safeguarding and showcasing

products across various industries. This article has provided a comprehensive

exploration of the manufacturing process, material considerations,

applications, design innovation, sustainability initiatives, quality assurance

measures, and technological advancements that define the intricate world of

vacuum forming tray production. Through a commitment to precision and innovation,

these manufacturers continue to shape the future of product packaging and

protection.

Vibest

International

excels as a leading vacuum forming tray manufacturer, utilizing

state-of-the-art processes to craft precision-engineered trays. Specializing in

thermoforming, Vibest produces trays with exceptional quality and versatility,

catering to diverse industries. With a commitment to innovation and

sustainability, Vibest continues to shape the future of vacuum forming in the manufacturing

landscape.

Social Media Marketing Strategies for Beginners

Mar 14 2023

(0) Comments