No More Mistakes with Flour Mill Machine Manufacturer

Mar 11 2023

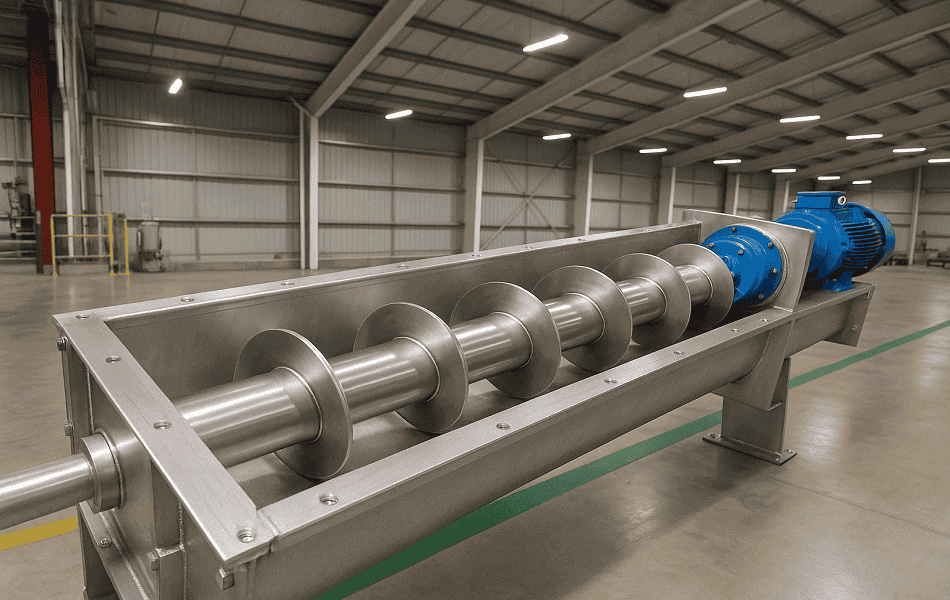

A screw conveyor is a reliable and efficient way to move bulk materials like powders, grains, and granules. Whether you are in food processing, construction, chemicals, or agriculture, choosing the right equipment is essential.

Finding the best screw conveyor manufacturer in India can be challenging. There are many suppliers, each offering different designs, materials, and prices. Making the wrong choice can lead to high costs, breakdowns, and poor performance.

This guide will help you select the right manufacturer for your project. We will discuss cost, quality, customization, service, and other important factors.

Before contacting manufacturers, be clear about what you need.

Ask yourself these questions:

Clear requirements will help manufacturers suggest the right solution. It also saves time during discussions and ensures you get accurate quotes.

2. Check the Manufacturer’s Experience

Experience matters when selecting a screw conveyor manufacturer.

Choose a company that has worked with businesses in your industry. Experienced manufacturers understand different materials, flow properties, and design challenges. They can recommend the right screw pitch, diameter, and speed for your project.

A manufacturer with a strong track record is more likely to deliver reliable, durable equipment.

Quality should be your top priority. A well-built screw conveyor will last longer and require less maintenance.

Ask about:

High-quality equipment ensures smooth operation, less downtime, and lower long-term costs.

Every project is different. The best manufacturer should offer customization.

Customization options may include:

Custom solutions ensure the screw conveyor fits perfectly into your process and increases efficiency.

Cost is important, but the cheapest option is not always the best.

When comparing prices, look at the total cost of ownership. This includes purchase price, installation, energy consumption, maintenance, and spare parts.

A slightly higher-priced but reliable conveyor can save you money in the long run. Avoid compromising quality just to reduce initial cost.

Good after-sales support is crucial.

Ask if the manufacturer provides:

Strong technical support reduces downtime and keeps production running smoothly.

Project deadlines are important. A delay in delivery can slow down your entire operation.

Choose a manufacturer who can meet your delivery schedule. Reliable manufacturers provide realistic timelines and keep you updated throughout production.

Customer feedback is a great way to judge a manufacturer’s reliability.

Look for reviews online or ask the manufacturer for client references. Speak to existing customers about their experience with product quality, service, and support.

Positive feedback is a sign that you are dealing with a trusted supplier.

If possible, visit the manufacturer’s factory.

This allows you to check their production process, quality control, and infrastructure. A well-organized facility shows professionalism and capability to handle your order.

A screw conveyor is not a one-time purchase. You will need spare parts, service, and possibly more equipment in the future.

Choose a manufacturer with whom you can build a long-term relationship. A good supplier becomes a partner in your growth and helps you upgrade as your production needs change.

Selecting the best screw conveyor manufacturer in India is not just about price. It requires looking at experience, quality, customization, service, and long-term support.

By understanding your project requirements and comparing multiple manufacturers, you can make the right choice. A reliable manufacturer will deliver durable equipment, provide great service, and help you achieve smooth operations.

Social Media Marketing Strategies for Beginners

Mar 14 2023

(0) Comments