No More Mistakes with Flour Mill Machine Manufacturer

Mar 11 2023

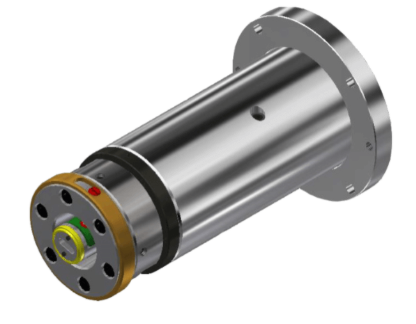

CNC spindles are the heart of modern machining operations, providing the speed, precision, and power necessary for high-quality production. Over time, even the most robust spindles can experience wear, misalignment, or component failure due to continuous use and environmental factors. Gilman Precision offers specialized spindle repair, rebuild, and refurbish services to restore performance, extend spindle life, and reduce downtime for manufacturing operations. Their services ensure that spindles continue to operate at peak efficiency, delivering consistent machining accuracy and reliable output.

A malfunctioning spindle can halt production, resulting in costly delays. Regular inspection and timely repair of spindles help maintain consistent operational flow and prevent unexpected machine stoppages.

Spindles are critical for maintaining precise machining tolerances. Worn or damaged components can lead to errors in part dimensions, surface finish issues, and reduced overall quality. Repair and rebuild services ensure that spindles operate within original specifications.

By addressing issues early and using high-quality replacement parts, spindle repair services extend the overall lifespan of machine tools, providing manufacturers with better return on investment.

Gilman Precision starts every repair with a thorough diagnostic assessment. Technicians identify issues such as bearing wear, imbalance, vibration, or motor failure to determine the most effective repair approach.

Precision bearings are essential for smooth spindle rotation. Gilman Precision replaces worn or damaged bearings and ensures perfect alignment to maintain spindle accuracy and stability during operation.

Unbalanced spindles can lead to uneven cutting, noise, and reduced component life. Spindle rebalancing services eliminate vibration, restore smooth rotation, and improve machining performance.

For motorized spindles, Gilman Precision inspects and repairs drive components, including the motor, coupling, and associated electronics, to restore full functionality and efficiency.

For heavily worn or damaged spindles, complete rebuild services replace critical components and refurbish the spindle housing. This process restores spindles to like-new condition, ensuring reliable performance and extended service life.

With decades of experience, Gilman Precision combines advanced engineering techniques with hands-on expertise to ensure precise spindle repairs. Each spindle is restored to meet stringent performance standards.

Replacement parts and materials are selected for durability and compatibility, ensuring long-term reliability and maintaining the spindle’s original performance characteristics.

Gilman Precision understands the impact of downtime on manufacturing operations. Their repair processes are designed to be efficient without compromising quality, minimizing production interruptions.

Every spindle repair is tailored to the specific requirements of the machine and application. Whether standard CNC spindles or high-speed precision models, Gilman Precision delivers solutions that meet exacting operational needs.

High-precision spindles are essential for machining aerospace components. Gilman Precision repairs and rebuilds spindles to maintain strict tolerances required for aerospace production.

From engine components to chassis parts, automotive manufacturing relies on spindle performance for speed and accuracy. Spindle repair services ensure uninterrupted production.

Medical components demand extreme precision. Gilman Precision restores spindles used in medical machining to ensure consistency and quality for critical applications.

Spindle repairs also support industries such as energy, electronics, and defense, where reliable machining operations are essential for efficiency and product quality.

Frequent checks for vibration, noise, and temperature changes help detect early signs of wear or misalignment.

Proper lubrication of bearings and regular cleaning prevent premature wear and maintain smooth operation.

Periodic rebuilds based on spindle usage and performance help avoid catastrophic failures and extend equipment life.

Tracking spindle performance and maintenance history allows for informed decisions about repairs and refurbishments.

Spindle repair, rebuild, and refurbishment are critical services for any manufacturing operation that relies on CNC machinery. Gilman Precision provides comprehensive solutions to restore spindle performance, improve reliability, and extend equipment life. With expert diagnostics, precision engineering, and high-quality components, their services ensure that spindles operate at peak efficiency, maintaining accuracy and consistency across all applications. Choosing Gilman Precision means minimizing downtime, optimizing productivity, and protecting your investment in machining equipment.

For manufacturers seeking dependable spindle repair services, Gilman Precision delivers unmatched expertise, tailored solutions, and long-term value, ensuring spindles continue to drive precise and efficient production cycles.

Social Media Marketing Strategies for Beginners

Mar 14 2023

(0) Comments