No More Mistakes with Flour Mill Machine Manufacturer

Mar 11 2023

Modern warehouses in Malaysia face increasing pressure to move goods quickly and securely. As demand rises, so does the need for dependable tools that keep packaging lines smooth and workers focused. That’s where machines like the vacuum sealer machine step in.

This tool tapes and closes cartons with precision and speed. It takes over repetitive tasks and brings more control to the end of the production process. Companies that once relied on manual taping now use automatic solutions to reduce error, increase efficiency, and standardise their output.

In this article, we explore why these machines have become essential, how they work, and what to consider when choosing one.

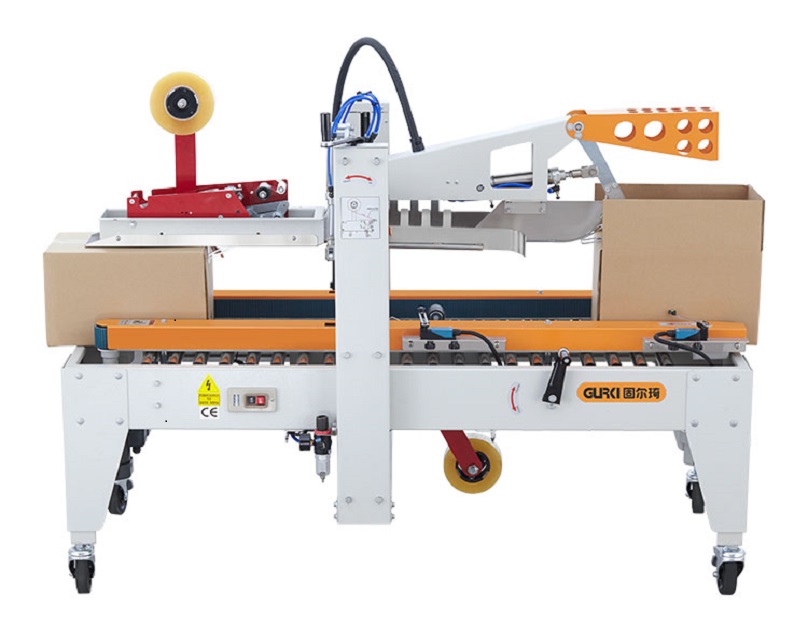

Before diving into benefits, it helps to define the machine itself. A carton taping machine, also known as a carton sealer, handles one of the final—but most important—stages of packing. It folds flaps and seals cartons, readying them for shipment or storage.

Manual taping depends on workers using tape guns. It works for small volumes but gets tiring over time. It also leads to uneven taping, tape waste, and slower packing speeds.

In contrast, an automatic taping machine brings consistency. It seals boxes at a steady pace with no breaks or fatigue. Over time, this boosts productivity and improves appearance.

Sealed boxes represent your brand. Neat, secure taping shows care. Messy tape lines send the wrong message. Machines produce even, clean seals across every box.

Switching to automatic systems does more than speed up work. It improves safety, reduces waste, and sharpens your bottom line.

Malaysia’s logistics and e-commerce sectors are growing fast. Fulfilment centres handle more packages than ever. A delay at the packing stage slows everything that follows.

Carton-taping machines reduce that risk. They support industries like:

These machines help companies meet tight shipping windows and increase customer satisfaction.

Not all boxes are the same. That’s why carton sealer machine options vary based on box type and line setup.

The best choice depends on how many box sizes you handle and how your workers load the machine.

When selecting a machine, watch for features that match your output needs and space.

Below is a table that summarises different machine types based on key traits. This helps match machine style to job type:

Machine Type | Best For | Adjusts to Box Size | Speed |

Uniform Sealer | Same-sized boxes on a fixed line | No | High |

Random Carton Sealer | Mixed sizes in the same production run | Yes | Moderate |

Top and Bottom Sealer | Full closure in one step | Some models do | High |

Side-Belt Drive Machine | Heavy or tall boxes | Depends on model | Medium |

This helps choose the right carton sealer machine without trial and error.

Installing a new taping machine takes planning. Space, box flow, and line speed all matter. Most machines roll into place and fit into your line without complex tools.

Workers need a short training session to load tape rolls, adjust settings, and fix jams. After that, the machine runs with little attention.

Some machines include sensors to detect box presence. Others use manual push-feed systems. Picking the right method depends on your team’s workflow.

Like any machine, tapers need regular checks. But their simple build makes them easy to maintain.

In larger factories, tapers often connect with other machines. These might include:

With proper layout planning, the vacuum sealer machine becomes part of a smooth, hands-free packaging system.

Safe machines protect people and products. Look for units with:

Machines should also rest on stable feet or locking wheels. This prevents shifting during use.

Reducing tape waste helps the planet. Machines that use less tape and produce fewer failed seals save both materials and disposal costs.

Lower maintenance means fewer replacement parts, saving money over time. Machines that run smoothly also use less power.

In a busy Malaysian factory, these small gains lead to strong results.

Warehouse managers in Malaysia report higher order throughput after switching to automation. Workers focus more on value tasks and less on tape issues.

Teams also note fewer tape jams and damaged boxes, which helps reduce returns and improve customer feedback.

These changes show how machines improve not only efficiency but also quality.

Packing is the final step before products meet your customers. That makes it one of the most important stages in your process. The vacuum sealer machine offers a reliable, simple, and efficient way to seal cartons with speed and care.

As Malaysia’s businesses grow, machines like the carton sealer machine become essential partners in that journey. They help your team keep up, reduce stress, and maintain the high standards your clients expect.

Investing in automation is not just about saving time. It’s about creating a system that works better for everyone—now and in the years to come.

Social Media Marketing Strategies for Beginners

Mar 14 2023

(0) Comments